The Benefits Of Using CNC Machining In The Automotive Industry

AI has been around in the automotive industry since the start of the twentieth century and is now a high-value sector. As cars become safer and manufacturers become more invested in state-of-the-art technology, new innovative components are being continuously introduced. One of these is CNC machining. CNC machining can create a range of heavy or light-duty automotive parts that make cars more powerful, fast, and efficient.

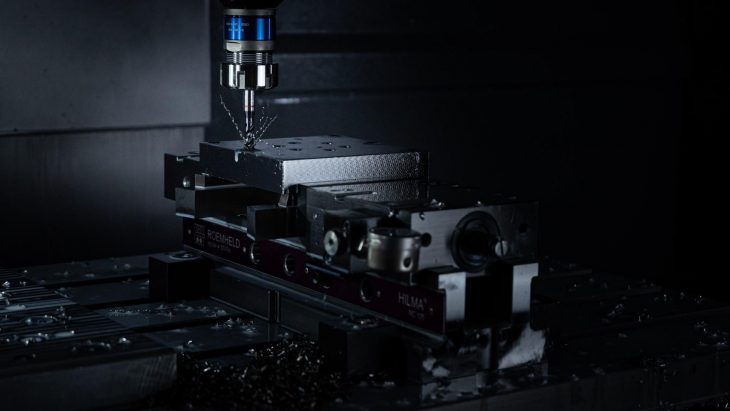

A lot of heavy machinery and robots are being frequently used in manufacturing as they have been carrying out assembly and welding in a much shorter time than it would be possible with human hands. Today, many car parts and components are made using CNC machining including carrying out tasks like milling, drilling, and turning.

CNC machining is excellent for prototyping and production as it can be completely computer-controlled. This means that everything is done automatically, making it more efficient than before. Read on to learn more about the use of this technology in the automotive industry.

CNC Machining’s Role In The Automotive Industry

CNC machining is a versatile manufacturing technique that can produce parts for a wide range of industries, including cars and vehicles. Some of the most important car parts that are made with the help of CNC machining are starter motors, interior panels, gearboxes, and cylinder heads.

Starter motors. The production of more complex metal parts like starter motors usually involves the use of CNC machining. This type of car part can be customized to meet the customer’s exact specifications and greatly improve performance, durability, and reliability.

Interior panels. Car parts like dashboards are often made using this technology. The machines offer the high precision required to machine a dashboard frame from a block of raw plastic material. It also makes it easier to align the gas gauge, speedometer, and indicator lights when installing them.

Gearboxes. The gearbox is the second stage in a car’s transmission system. It consists of multiple shafts and gear components. Even the smallest and most intricate components of the gearbox are cast and then finished with CNC drilling and milling equipment.

Cylinder heads. CNC machining is used to cut engine blocks and cylinder heads for the internal combustion engine. It is mainly used in limited runs of more complex cylinder heads or customized engine models. The cylinder heads typically come from a solid aluminum block which is relatively easy to work with. Other common parts that are often machined using CNC include alternator housings, brake system valves, and fuel pump systems.

Benefits Of Using CNC Machining

Automation

Automation has made the process of manufacturing vehicles easier and more efficient. For instance, in some manufacturing environments, robots and other advanced technologies help take care of the basic production tasks, freeing up the workers to focus on more creative tasks.

Accuracy And Precision

CNC machines are great for car manufacturing since they offer a very high level of accuracy when it comes to producing critical components. With the latest CNC machinery settings, the likelihood of an error is minimal. This benefit of CNC machining is so important to the automotive industry due to the significant requirements of high standards with high tolerance levels because any malfunction in a vital automobile component can have disastrous consequences.

Repeatability

CNC technology permits manufacturers to produce the same part multiple times without any inconsistency. CNC machining is proving to be very useful in the automotive industry since a lot of companies are manufacturing huge volumes of similar products. Over 70 million cars are manufactured and sold every year, so the demand for car parts is constantly high.

Production Speed

The most significant benefit CNC machining offers to the automotive industry is its speed. The production of various car parts is carried out automatically, so no human limitations need to be factored into the procedure. This benefit becomes more apparent when high-volume machining of a specific part takes place. The computer instructions can be repeated as many times as required without any human involvement. Besides, numerous concrete steps can be taken in the production planning process to optimize and speed up the machine’s run time, including part tolerances and material choice.

Final thoughts

This manufacturing technology is heavily relied upon in the production of different car components such as oil filters, brake calipers, and exhaust manifolds. CNC machining can also be used to create functional prototypes of car components for design testing. This speeds up the process significantly and allows you to test designs quickly before building them. One thing is certain, though, CNC machining

The post The Benefits Of Using CNC Machining In The Automotive Industry appeared first on Motorward.